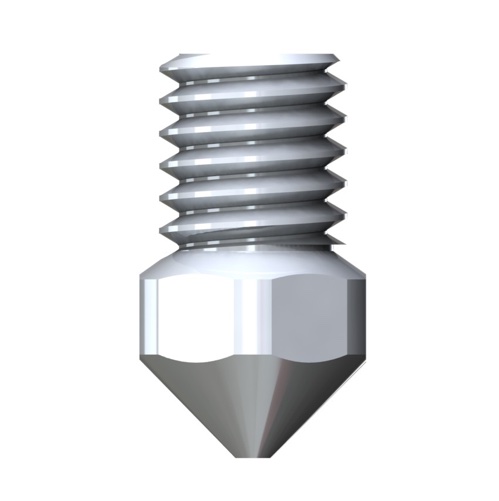

Description

This fantastic newly developed product by 3D Solex has a core of stainless steel and a multi-component molecularly interlocked tempered surface with 2 main advantages:

1) PLA ( or any other filament we know of ) simply refuses to stick to it.

2) Cold Pulls work so much better, the inside of the nozzle is “ICE” too.

3) Its surface is much more wear resistant than that of stainless steel, so it will last much longer

printing abrasive filaments. Compared with brass, – it is in a class of its own.

It also works exceptionally well with chemically challenging chemicals, like glow, flexible materials, + many more.

These are the three fantastic advantages of this nozzle.

Now blobs of filament will not be carried around and depositet on your print.

It still prints slower than a brass nozzle.

Downside: A stainless steel based nozzle will not allow you to print as fast as a brass one.

Use: Run-in period of 2 hours at max 220C. This hardens/tempers it, after that, Max temp 280C.