Description

For Prusa I3 Mk3.

This sensational kit for the Prusa I3 Mk3 will transform your printer.

Safely change nozzle using our tools included in kit.

Ramp up plastic output thanks to our patented core heating nozzles and fully utilizing the Bondtech feeder already installed in your printer.

By combining nozzle size, layer height and speed you can achieve up to 30 cubics / second.

Kit now ships with 7mm fixed wrench like in photo.

Safe installation, no risk to block and cables! The hand-tool in video is not included in kit.

If you spool to around 18 minutes, you will see the difference!

Included in kit:

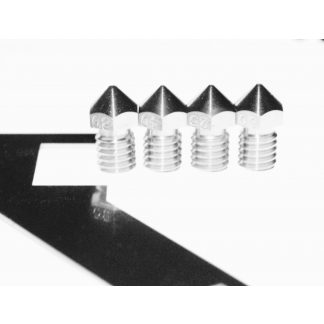

Nozzles

0.25 mm (not Matchless, as the core heating will have little effect at the low throughput of this tiny nozzle)

0.40 mm (Matchless; core heating)

0.60 mm (Matchless; core heating)

0.80 mm (Matchless; core heating)

The nozzles are brass, and are coated with a layer to prevent them from reacting with the aluminium block.

This ensures that you can change nozzles without fear of destroying the heater block.

Tools

Nozzle Changer for Prusa I3.

Nozzle socket ( you provide wrench 1/8 ) or print a Torque Wrench found here.

Silicon sock for block (conserves heat and protects heater block)

What it does

This kit allows “volcano-speeds” by just changing the nozzle. The Matchless nozzles, patented by 3D Solex, have a melting zone much bigger than an ordinary nozzle. An ordinary nozzle is melting the filament from the “outside” and trying to push the coldest part (centre of filament) through the exit hole of the nozzle.

The core heating effect of the Matchless nozzles is melting the middle of the filament, that part which you wish to push out through the nozzle.

What the others must do: Lengthening the heating zone, which has a negative effect on retractions, adds weight to the head and is costly.

Advantages

1) You can now change nozzle risk free and hazzle free, by using the tools included in this kit. Change nozzle in seconds, without risk of destroying the sensors of the printer or the heat break.

2) Print with a much higher troughput, by configuring a combination of :

a) nozzle size

b) layer height

c) printing speed.

3) Print with a lower temperature. Since you are effectively melting the plastic you can print at a lower temperature than before. Using the existing settings of your previous print, you can lower 5-15 C.

4) Wide range of nozzles sizes (mm) available from 3D Solex:

0.25, 0.40, 0.50, 0.60, 0.80, 1.0, 1.2, 1.5, 2.0

Example: You can now print a vase with a 0.80mm nozzle at the same or higher speed than you could using a 0.40mm nozzle previously. This way you only need 1 pass to make a 0.8mm wall.

* This fantastic kit allows up to 30 cubic/mm per second by changing the Nozzle Only! Tools for safe changing of nozzles included!

* This fantastic kit allows up to 30 cubic/mm per second by changing the Nozzle Only! Tools for safe changing of nozzles included!