Description

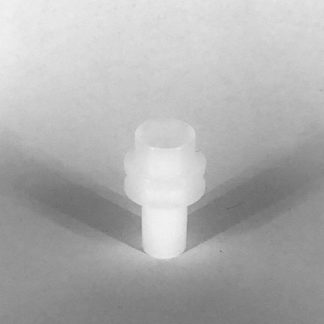

Very useful! Great pay-back! Will save you at least 1, probably many hot end re-builds! Fact: bought together with our own PTFE coupler in i kit named TF2K, we guarantee the PTFE for 6months unlimited printing (excludes physical abrasion of PTFE). If you print with ABS or PLA or any non-“filled” filament, your PTFE will last more than 1.000 hours continuous use. Usage: Unplug PTFE from steel coupler, insert I2K, re-insert PTFE. Finished. Steel coupler must be turned all the way down to block, and only half turn back up allowed for sync in dual setup. This precision machined upgrade insulates the Teflon coupler from the hot end top end, enabling the Teflon coupler to live for a long time. (image is from engineering sample). The Teflon will still deform, but much more slowly. It`s underside is no longer in contact with the Hot End, but on retractions, the hot plastic still touches the inside wall. Over time the Teflon still forfeits sufficiently of it`s properties to start imploding and “squeezing” the filament and hot retracted plastic. This part is in shape of a “wafer chip” and installs easily together with “Matchless V3 Block”. It is a perfect fit, so your SS coupler (the steel item with the radial holes in it) needs to be totally clean inside. HOW TO INSTALL – RIGHTLY! I2K Chip is Inside under Teflon The I2K will save your PTFE Teflon coupler from deforming for a long time, and save you from print head assembly rebuilds. We have 1.000+ hours at 260C varied printing, and no deforming. A lot of retractions @260+ influences longevity of the Teflon negatively. The chip itself can take 300C continuously, and will outlast your printer if you print at maximum this temperature. The I2K rests inside the steel coupler with the radial holes. It protects the PTFE from the hot end. Attention: The steel coupler is screwed down all the way, then back up until 1/2 turn to adjust dual setup, if needed. This makes higher pressure. WRONG- Steel Coupler not far enough down. May cause leaks.